@rahix This will be a bit:

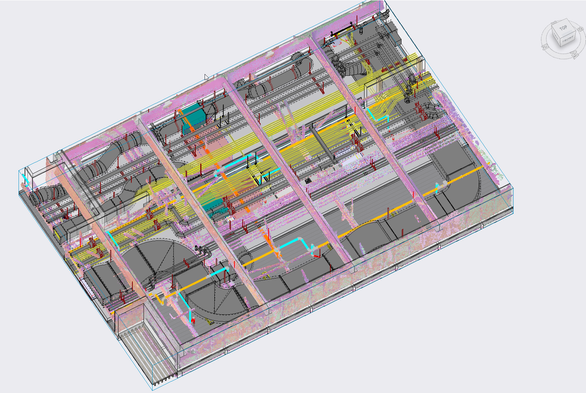

I use Autodesk Revit for this work.

It is called Building Information Modelling (BIM).

We call the process here Virtual Construction, and this occurs after a generalized schematic design is chosen from an engineer.

The Revit software does indeed handle cable tray, pipe bus, bus duct, air duct, conduit, racking, piping, and more mechanical systems.

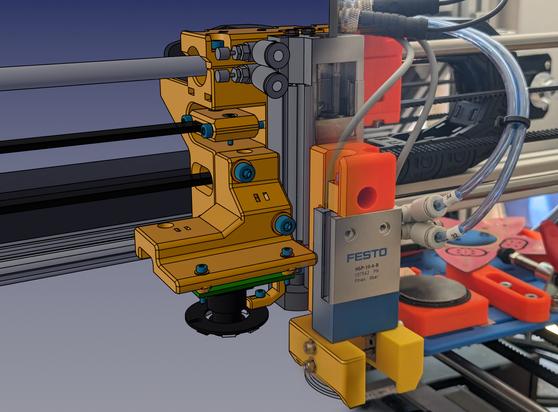

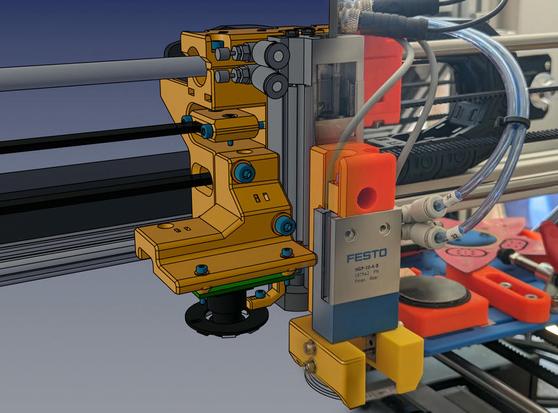

This 3D laser scan was done by a Trimble X7 scanner, and then onsite there are Robot Total Stations that locate the hangers you see depicted holding up the HVAC Ductwork system peices.

I programmed the system that hangs these parts (C#). Each component, once segmented and quality controlled, will be physically fabricated as seen in the 3d model image. Those will then be installed onsite, and in a few months, we will be able to AR the site and see how well it all matches in the end.

This is like #3dPrinting on all the drugs.