The glider now has 12 pounds of lead shot and epoxy added to dead space in the very end of the tail boom.

My initial estimate of volume indicated that I could add 8 - 10 pounds this way. I'm pleasantly surprised, and I didn't make a chocolate covered mess of things as I was pouring this goop into the tail.

I need to add a few more pounds to the tail. Phase two of this project will use lead plate, bolted to the vertical fin spar. (I need to unroll the 1/4-inch plate first, then develop a template to cut the lead.)

I could not add the epoxy/lead shot mix all at once because of the exothermic reaction of epoxy. When mixed epoxy is in a thick blob (instead of a thin layer), it generates enough heat to warm itself...which accelerates the chemical reaction...releasing more heat...further accelerating the reaction.... I have seen epoxy smoking hot because of this, so I added a bit, waited a half hour, checked temperature with an IR non-contact thermometer, added a bit more when it was clear that the exotherm was only very mild, etc. That took a while, but turned out well.

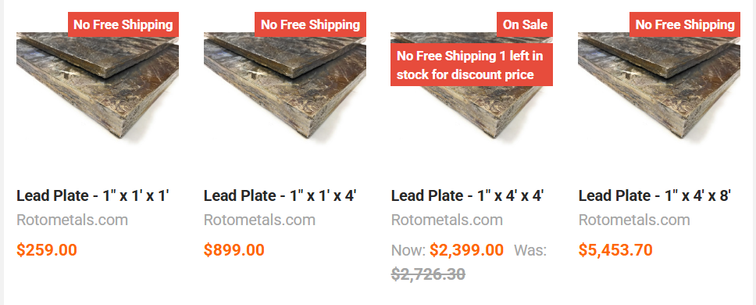

I note that Roto Metals has a discount on some 1-inch lead plate. Get your fork lift ready. No free shipping!

https://www.rotometals.com/lead-sheet-plates/sheet-lead-1-64-lbs-sq-ft/

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Ballast #Math #Density #Exothermic #Chemistry #Thermodynamics #Lead #Epoxy