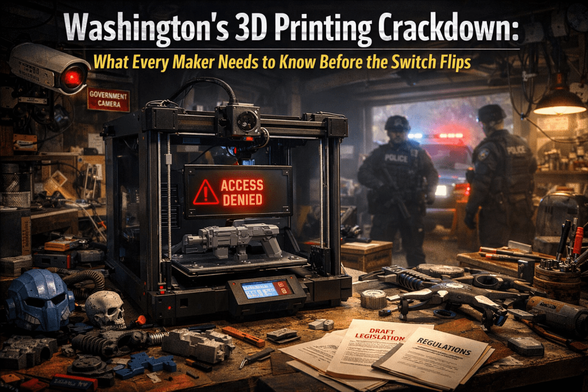

Washington’s 3D Printing Crackdown: What Every Maker Needs to Know Before the Switch Flips

4,489 words, 24 minutes read time

If you run a 3D printer in Washington State, the ground under your workshop just shifted. Not with the whine of stepper motors or the smell of hot PLA, but with legislation. Over the last few years—and accelerating hard into 2025 and 2026—Washington lawmakers have moved to regulate, restrict, and in some cases outright ban specific uses of 3D printing tied to firearms. The target is so-called “ghost guns,” but the blast radius extends far beyond firearms hobbyists. It reaches into garages, makerspaces, classrooms, and basements where men quietly build, tinker, and solve problems one layer at a time.

This article breaks down who is pushing these laws, what they actually say, when they take effect, where enforcement may land, why lawmakers argue they’re necessary, and how they could change the future of consumer 3D printing in Washington. If you own a printer—or are thinking about buying one—this is information you need before you hit “Print.”

The Laws Driving Washington’s 3D Printing Ban

Washington’s current posture toward 3D printing didn’t materialize out of thin air. It has been building quietly for years, driven by a growing concern inside state government that advances in personal fabrication have outpaced existing firearms law. The first major inflection point came in 2019 with the passage of House Bill 1739. That law made it illegal to manufacture, possess, sell, or transfer an undetectable or untraceable firearm—what lawmakers and media often label a “ghost gun.” The focus was clear and narrow. The state targeted the finished weapon, not the means by which it was made.

At that time, 3D printers were treated no differently than any other shop tool. A printer was just a machine, functionally equivalent in the eyes of the law to a drill press, milling machine, or lathe. What mattered was the outcome. If you crossed the line into producing an illegal firearm, you were liable. If you didn’t, the state had no interest in your equipment, your files, or your workflow.

That distinction is what the latest wave of legislation effectively erases.

House Bill 2320 and House Bill 2321, introduced for the 2025–2026 legislative biennium, represent a fundamental shift in how Washington approaches regulation. These bills move “upstream,” away from the completed firearm and toward the process of manufacturing itself. Under this framework, the act of making becomes regulated before a physical object ever exists. The implications are significant, because once manufacturing is the target, the tools, software, and digital designs involved inevitably fall under scrutiny.

HB 2320 expands the definition of illegal firearm manufacturing to explicitly include methods involving CNC machines and 3D printers. This is a legal tightening that reduces ambiguity but also widens the net. The law no longer cares whether the manufacturing process is traditional or additive; if the output is deemed unlawful, the process itself is implicated.

HB 2321 goes much further and is the bill that has set off alarms within the 3D printing community. It proposes requiring 3D printers sold, distributed, or operated in Washington State to include what the bill calls “firearm-blocking features.” In practical terms, this means embedded software or firmware designed to detect and prevent the printing of firearm components. The bill does not limit this requirement to commercial manufacturers or industrial systems. As written, it potentially applies to consumer-grade printers sitting on a workbench in a spare bedroom.

The penalties outlined in HB 2321 are not symbolic. Violations can carry felony charges, multi-year prison sentences, and fines that can climb into the tens of thousands of dollars. Importantly, liability is not limited to someone intentionally printing a firearm. The bill’s language raises unanswered questions about responsibility for modified firmware, open-source machines, file storage, and even the act of making a printer “available” without required controls.

Washington Attorney General Bob Ferguson has been explicit about the state’s reasoning. In public statements supporting the legislation, he has argued that 3D-printed firearms are uniquely dangerous because they are untraceable, difficult to detect, and increasingly recovered at crime scenes. From the state’s perspective, waiting until a weapon exists is too late. The logic is preventative: if the technology enables illegal outcomes, the technology itself must be constrained.

That framing marks a turning point. For the first time, Washington law treats a general-purpose manufacturing tool not as neutral equipment, but as a potential vector of harm. For makers, engineers, and hobbyists, that distinction matters. It is the difference between regulating behavior and regulating capability—and once that line is crossed, it becomes much harder to draw clear boundaries around what remains permissible.

How the State Says This Will Work

On paper, the concept behind the proposed laws sounds straightforward, almost reassuring in its simplicity. Lawmakers envision a future where 3D printers actively scan STL files, G-code, or other design instructions before a job begins. Those files would be compared against a database of prohibited firearm components. If the system detects a match—or something it believes resembles a restricted part—the printer simply refuses to run the job. No warning shots, no gray area. The print never starts. In theory, it functions like a digital safety interlock, quietly preventing misuse before it happens.

That theory begins to unravel the moment it meets real-world manufacturing workflows.

Experienced engineers, software developers, and long-time makers immediately see the problem: 3D printing files do not carry intent. An STL file is nothing more than geometry—triangles describing a shape in three-dimensional space. A block with holes could just as easily be a camera mount, a custom bracket for a shop jig, a drone component, or a piece of test geometry for tuning extrusion settings. Context is everything, and STL files have none. They do not know what they are “for,” only what they look like.

G-code strips things down even further. By the time a slicer outputs G-code, the file contains no object identity at all. It is a list of instructions telling motors where to move, heaters when to warm, and fans when to spin. From a technical standpoint, asking a printer to determine whether G-code represents a prohibited object is like asking a CNC mill to judge the moral intent behind a toolpath. The data simply does not support that kind of inference.

This is where the practical risks begin to stack up. Any detection system aggressive enough to reliably block firearm components would almost certainly generate false positives. Legitimate prints—replacement parts, fixtures, prototypes, or educational models—could be flagged and blocked with no clear explanation. Worse, because the proposed requirements center on firmware-level controls, users may have little visibility into why a job failed or what triggered the block.

Tom’s Hardware, a publication widely respected among PC builders, engineers, and makers, highlighted this gap in its coverage of the legislation. The outlet noted that the bill’s language leaves major questions unanswered around enforcement, technical feasibility, and error handling. There is no clear standard for how accurate detection must be, how databases would be maintained, or how disputes would be resolved when a printer misidentifies a harmless design.

The concern extends beyond inconvenience. Mandatory scanning and blocking mechanisms introduce new failure points into machines that many users rely on for work, education, and small business production. Firmware corruption, slicer incompatibilities, and locked-down systems could make printers less reliable, harder to repair, and more opaque to the people who own them. For a community built on transparency, modifiability, and iterative problem-solving, that represents a fundamental shift in how these tools function.

At its core, the issue is not whether illegal firearms should be regulated. It is whether general-purpose manufacturing tools can realistically be tasked with understanding context, intent, and legality based solely on shapes and motion commands. For many in the 3D printing world, that expectation feels less like a safety feature and more like asking a wrench to decide whether a bolt looks suspicious before it turns.

What This Means for Regular 3D Printing Guys

For the average male 3D printing enthusiast—someone cranking out brackets, enclosures, jigs, drone parts, camera mounts, or custom shop tools—the fear isn’t that you’re secretly running an arms factory out of your garage. The fear is uncertainty. It’s not knowing where the line actually is, or when it might move. Most makers aren’t looking for trouble; they’re looking for solutions. They print because it’s faster, cheaper, and more satisfying than waiting three days for a part that should’ve cost five bucks.

These bills blur the line between intent and capability in a way that makes technically minded people uneasy. A printer that could produce a restricted component becomes suspect, even if it never does. That distinction matters. Nearly any modern FDM or resin printer is capable of producing a wide range of shapes. Under this framework, capability itself becomes a risk factor, not behavior. For people who understand how flexible and general-purpose these machines are, that feels like a fundamental misunderstanding of the technology.

There’s also real concern about liability. Makers question whether modified firmware, open-source printers, or self-built machines suddenly fall into a gray area. What about older printers that can’t support mandated updates? What about machines running community-developed firmware like Marlin or Klipper? The bills offer little clarity on who bears responsibility when a system lacks required controls—the user, the seller, the manufacturer, or the developer who wrote the code. For hobbyists and small operators, ambiguity is often more dangerous than outright prohibition.

Then there’s enforcement creep. Once file-scanning or blocking requirements exist, expanding them becomes technically trivial. What starts with firearm components could, in theory, extend to other regulated items, proprietary shapes, or restricted designs. Even if lawmakers have no current intention to go further, the infrastructure would already be in place. For a community that values control over its tools, that possibility lingers in the background.

One Reddit user summed up the mood succinctly, saying the legislation feels less like regulating guns and more like regulating printers themselves. That sentiment resonates because 3D printing culture has long been rooted in open-source hardware, self-repair, and modification. Makers are used to upgrading their machines, flashing new firmware, and tuning performance to suit their needs. Being told that a core tool must now include mandatory restrictions feels like buying a project truck only to discover the ECU phones the state every time you turn the key—and refuses to start if it doesn’t like where you’re headed.

For many, the concern isn’t ideological. It’s practical. It’s about whether a trusted tool remains a tool—or becomes something you have to look over your shoulder to use.

The Broader Legal Context

Washington is not acting in isolation. States such as New York and New Jersey have already passed laws aimed at so-called ghost guns, and federal agencies have steadily pushed to redefine firearm frames and receivers to include partially completed or printable components. Across the country, lawmakers are wrestling with how to regulate weapons that can be manufactured outside traditional supply chains. What sets Washington apart is how aggressively it shifts focus away from the finished firearm and toward the tools, software, and digital processes that make fabrication possible in the first place.

Most existing laws still hinge on possession or manufacture of an illegal weapon. Washington’s proposed framework moves the legal boundary earlier in the chain. Instead of asking whether someone made or possessed a prohibited firearm, it begins asking whether the means used to make something were compliant. That shift is subtle on paper, but profound in practice. It raises a question many makers ask bluntly: if a printer lacks required controls, does simply owning or using it turn someone into a criminal by default?

As written, the answer is no—ownership of a 3D printer alone is not a felony. The proposed laws do not state that merely possessing a non-compliant machine automatically makes someone a criminal. There is no blanket ban on 3D printers, STL files, or generic mechanical parts. However, the concern lies in how prohibited conduct is defined. HB 2321 focuses on the operation, distribution, or availability of printers that lack mandated “firearm-blocking features.” That means liability is tied not to what a person intends to do, but to whether their equipment meets a new legal standard.

This is where older 3D printers come into the picture. Legacy machines—early consumer printers, DIY kits, custom builds, and heavily modified systems—were never designed to scan files or enforce content restrictions. Many cannot be retrofitted to do so. Others run open-source firmware precisely because it avoids centralized control. The legislation does not clearly state whether these machines are grandfathered in, whether owners are expected to upgrade or replace them, or whether continued use becomes unlawful once the requirements take effect. That lack of clarity fuels anxiety, not because people expect mass arrests, but because the legal ground feels unstable.

The same uncertainty applies to generic parts. Take something as mundane as a screw. A machine screw, roll pin, or threaded fastener is not a firearm component under Washington law. Owning an STL file of a screw does not make someone a felon. Possessing an actual screw—printed or metal—does not imply criminal intent. Courts have historically required context and purpose. A box of screws at a hardware store does not become contraband because some screws can be used in firearms.

The complication arises when prevention is pushed into software. STL files are just shapes. G-code is just motion. A cylinder with threads could be a camera mount, a jig component, a shop repair part, or a fastener used in a firearm assembly. The law assumes that detection systems can reliably tell the difference. Technically, that assumption is weak. Legally, intent still matters—but a blocking algorithm does not understand intent. It only decides yes or no.

This is why fears of “automatic felons” persist, even if they are not strictly accurate. The statutes do not criminalize screws, files, or printers outright. What they do is create conditions where lawful activity can be disrupted, discouraged, or placed under suspicion because tools are expected to infer legality before anything illegal exists. That shifts the burden. Instead of the state proving wrongdoing after the fact, users may feel pressure to prove compliance in advance, simply to keep their machines running.

Washington’s approach is informed by earlier legal momentum. In 2018, the state successfully challenged a federal attempt to deregulate online distribution of 3D-printed gun files. Courts sided with the argument that public safety concerns justified limits on digital designs. That precedent is now being applied domestically, with state law filling gaps where federal regulation remains unsettled.

Legal scholars note that this strategy raises unresolved constitutional questions. At issue are concepts like prior restraint, software as speech, and whether code can be regulated as conduct rather than expression. Those debates will likely be settled in court—but court cases take years. Legislation moves much faster.

For now, Washington is advancing a regulatory model that treats capability as risk and neutrality as insufficient. For owners of older printers, open-source systems, and general-purpose machines, the immediate effect is not criminalization, but legal fog. And in the world of regulation, uncertainty often does more to change behavior than enforcement ever could.

Why This Hits the Maker Community Hard

Men continue to dominate the hobbyist and semi-professional 3D printing space, particularly in mechanical, engineering, machining, and fabrication niches. Walk into a garage workshop, a makerspace, or an industrial prototyping lab, and the pattern is consistent. These are men who grew up fixing things, tearing machines apart to see how they worked, and putting them back together better than before. For them, 3D printing isn’t a novelty or a toy. It’s a problem-solving tool. It’s how a broken part gets replaced at midnight without waiting a week for shipping. It’s how a jig gets built instead of bought. It’s how a design moves from idea to object without asking anyone’s permission.

At its core, 3D printing represents control. Control over tools. Control over repairs. Control over outcomes. It removes friction between need and solution. That autonomy is the appeal. When something breaks, you don’t fill out a form or wait on a supplier—you open CAD, measure twice, and make the part yourself. For many men, especially those with mechanical or engineering backgrounds, that independence is not just convenient; it’s foundational to how they think and work.

Washington’s approach cuts directly across that grain. Mandatory restrictions embedded at the machine level fundamentally change the relationship between maker and tool. A printer that scans files, blocks jobs, or enforces rules before a print begins is no longer a neutral instrument. It becomes a gatekeeper. Even if a user never prints a firearm-related part, the knowledge that the machine is pre-censored alters how it’s perceived. Trust erodes. The tool stops feeling like an extension of the craftsman’s hands and starts feeling like a system that answers to someone else first.

That shift matters because makers tend to form strong attachments to their equipment. Printers are tuned, modified, repaired, and optimized over time. Firmware is flashed. Hardware is upgraded. Profiles are dialed in through hours of trial and error. These machines are not disposable appliances; they are working partners. Introducing mandatory controls that limit modification or introduce opaque decision-making feels less like a safety feature and more like an intrusion.

For most men in this space, the objection is not political. It’s principled. It’s about whether tools remain neutral and user-controlled, or whether they become conditional—useful only as long as they behave according to rules written far from the workshop. The analogy many reach for is simple and telling. It’s like discovering your favorite wrench suddenly refuses to fit certain bolts because someone, somewhere, might misuse it. You didn’t change. Your work didn’t change. But the tool did, and now it decides when it’s willing to cooperate.

That loss of agency strikes at something deeper than convenience. It challenges a mindset built around competence, self-reliance, and responsibility. For a community that values building over buying and fixing over replacing, the idea that a tool must now second-guess its owner feels like more than regulation. It feels like a redefinition of who is trusted to create—and under what conditions.

Where This Is Likely Headed (and Why Supreme Court Gun Law Matters)

If these laws pass as written, the immediate effects could ripple across workshops and online communities. Manufacturers may respond by limiting sales in Washington or shipping firmware that enforces prints, while open-source communities could fracture over whether and how to maintain compliant versions of their software. Enforcement is likely to be complaint-driven at first, but the chilling effect on creativity, file sharing, and collaborative development may arrive long before the first prosecution.

Washington’s approach does not exist in a vacuum. Federal constitutional law, particularly Supreme Court interpretations of the Second Amendment, sets boundaries that could shape how courts view upstream regulation of machines and digital design files. Recent rulings and pending cases highlight both the opportunities and the obstacles for a law that targets tools rather than finished firearms. It is important to note that nothing here is legal advice. I am not a lawyer, and readers concerned about compliance or personal risk should consult a licensed attorney before taking any action.

The Supreme Court’s 2022 decision in New York State Rifle & Pistol Association v. Bruen struck down New York’s “proper cause” requirement for concealed carry, establishing that modern firearm restrictions must be justified with reference to a historical tradition of firearm regulation. Courts must evaluate whether a regulation aligns with historical practices, and Washington’s requirement that 3D printers include software to block certain objects has no clear historical precedent. Under this framework, such requirements could face serious legal challenges.

The 2008 decision in District of Columbia v. Heller also informs the debate. Heller affirmed that individuals have a constitutional right to possess firearms for lawful purposes such as self-defense. While the Court recognized that some restrictions are permissible, it made clear that laws cannot place undue burdens on the right to own guns. Advocates of gun rights often point to this case to argue that barriers that interfere with lawful access to tools and firearms could be constitutionally suspect.

Other Supreme Court cases under review could further constrain state regulation. For example, Hawaii’s strict carry restrictions on private property are currently being evaluated under the Bruen framework, and early signals suggest skepticism toward laws that broadly limit core Second Amendment rights. Lower federal courts have sometimes allowed restrictions in sensitive locations like schools or government buildings, but there is no clear precedent for regulating general-purpose manufacturing tools that could be used to make firearms. That makes Washington’s approach a legal frontier, likely to face challenges if it is enforced.

Washington’s proposed regulations are novel in constitutional terms. They do not simply regulate guns; they regulate the tools and digital processes that can be used to make them. There is no historical analogue for requiring general-purpose 3D printers to embed software that blocks certain designs, and the lack of precedent means courts will scrutinize these measures carefully. Supreme Court decisions like Bruen and Heller, along with ongoing cases, set a backdrop that could limit the state’s authority to regulate manufacturing tools in this way.

Ultimately, if Washington’s bill becomes law, it is almost certain to be tested in federal court, and possibly even at the Supreme Court level. How those courts balance public safety, innovation, and constitutional protections will shape not just this law, but the future of personal fabrication rights in the United States. Readers should be aware that this overview is for informational purposes, I am not a lawyer, and anyone concerned about legal risk should consult a licensed attorney before taking any action.

Final Thoughts—and Your Move

Washington’s 3D printing ban isn’t just about guns. It’s about who controls the tools we rely on every day, the machines we trust to fix, build, and innovate. For men who tinker in garages, run home workshops, or fabricate parts for drones, vehicles, or custom projects, this is more than policy—it’s personal. It’s about whether your printer is a neutral instrument in your hands, or a piece of hardware that comes pre-censored, pre-judged, and pre-policed. Imagine your favorite printer suddenly refusing to make a bracket or jig because a line of code says it might be part of something restricted. That’s not just annoying. It’s a loss of agency.

The stakes go beyond individual makers or the borders of one state. The 3D printing industry itself could take a major hit. Manufacturers may rethink shipping printers or firmware into Washington to avoid liability, resellers could suddenly be on the hook for products that were previously legal, and hobbyists or small shops might risk penalties simply for owning older machines or sharing design files. For a community built on tinkering, self-repair, and modification, that’s a shockwave. Overnight, a casual maker could theoretically become a target.

Even makers in states without such laws are not immune. Firmware updates, software restrictions, or national supply-chain decisions could spill over, effectively imposing Washington-style constraints on printers and parts far beyond state lines. A company that locks down its machines for one market could unintentionally lock out users elsewhere, and open-source communities may feel pressure to implement “safety” features that nobody wanted. The chilling effect could ripple across the hobbyist ecosystem, slowing innovation and creating a climate of caution that touches everyone.

This is the kind of moment where paying attention matters. These bills aren’t static—they’re moving. Decisions made in Olympia could ripple out to firmware updates, printer manufacturers, and open-source communities nationwide. You don’t have to be a lawyer or a lobbyist to have a voice, but you do need to understand what’s at stake: the future of personal fabrication, the freedom to innovate, and the practical ability to maintain, modify, and use your tools without fear of unintended legal consequences.

If you care about where this goes next, subscribe to the newsletter for updates as these bills move forward. Share your firsthand experience, technical insight, or concerns in the comments to join the conversation. The more makers speak up, the harder it is for policy to develop in a vacuum. If this issue affects your work, business, or even just your hobby, reach out to your state representatives and senators. Explain what it looks like on the ground when hobbyists, engineers, and small shops suddenly face restrictions that could make their everyday tools illegal. Lawmakers often respond to constituents who can clearly illustrate the practical impact of regulations.

Washington’s approach is testing the boundaries of control over technology and personal fabrication. How we respond now can influence not only this legislation, but the precedent for other states considering similar moves. Speaking up, sharing your perspective, and staying informed aren’t just civic duties—they’re ways to safeguard the culture of making and preserve the tools we depend on. For the 3D printing industry, it could mean the difference between thriving innovation and cautious stagnation, not just in Washington, but across the country. The next move is yours, and for makers, the stakes are worth the attention.

Call to Action

If this post sparked your creativity, don’t just scroll past. Join the community of makers and tinkerers—people turning ideas into reality with 3D printing. Subscribe for more 3D printing guides and projects, drop a comment sharing what you’re printing, or reach out and tell me about your latest project. Let’s build together.

D. Bryan King

Sources

Disclaimer:

The views and opinions expressed in this post are solely those of the author. The information provided is based on personal research, experience, and understanding of the subject matter at the time of writing. Readers should consult relevant experts or authorities for specific guidance related to their unique situations.

Related Posts

#3DPrinterFirmware #3DPrinterFirmwareLock #3DPrinterLegality #3DPrinterLegislation #3DPrinterOwners #3DPrinterRestrictions #3DPrintingAdvocacy #3DPrintingCompliance #3DPrintingCulture #3DPrintingDebate #3DPrintingEnforcement #3DPrintingEnthusiasts #3DPrintingFuture #3DPrintingHobbyists #3DPrintingIndustry #3DPrintingInnovation #3DPrintingLaws #3DPrintingLegalIssues #3DPrintingMarketImpact #3DPrintingNews #3DPrintingSafety #3DPrintingSoftwareLaws #3DPrintingTools #digitalFabrication #digitalFabricationRights #digitalManufacturingRegulations #DIYGunLaws #DIYManufacturing #firearmManufacturing #firearmRegulations #firearmBlockingSoftware #firmwareRegulations #ghostGuns #HellerCase #hobbyistMakers #hobbyistRights #homeFabricationLaws #homeWorkshopSafety #innovationRestrictions #legalUncertainty3DPrinting #makerCommunity #makerMovement #makerRights #NYSRPAVBruen #openSource3DPrinters #openSourceSoftware #personalFabrication #personalFabricationRights #printerCensorship #printerLiability #printingSafetyFeatures #SCOTUSGunCases #SecondAmendment #smallBusinessFabrication #STLFileRestrictions #techPolicy #toolControlLaws #Washington3DPrintingBan