Lasers Make PCBs the Old Fashioned Way

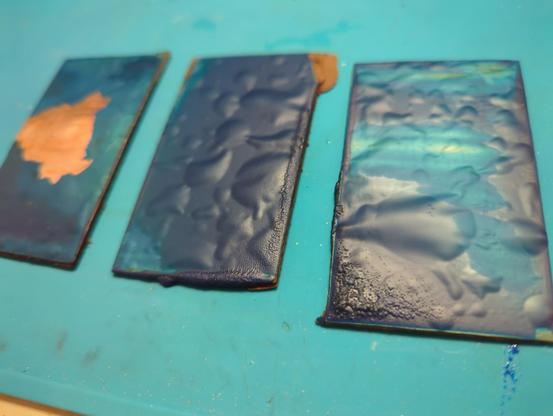

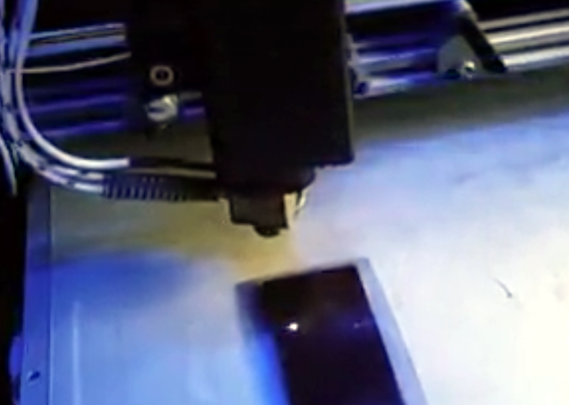

There are many ways to create printed circuit boards, but one of the more traditional ways involves using boards coated with photoresist and exposing the desired artwork on the board, usually with UV light. Then you develop the board like a photograph and etch it in acid. Where the photoresist stays, you'll wind up with copper traces. Hackers have used lots of methods to get that artwork ranging from pen plotters to laser printers, but commercially a machine called a photoplotter created the artwork using a light and a piece of film. [JGJMatt] sort of rediscovered this idea by realizing that a cheap laser engraver could directly draw on the photoresist.

The laser dot is about 0.2 mm in diameter, so fine resolution boards are possible. If you have a laser cutter or engraver already, you have just about everything you need. If not, the lower-power laser modules are very affordable and you can mount one on a 3D printer. Most people are interested in using these to cut where higher power is a must, but for exposing photosensitive film, you don't need much power. The 500 mW module used in the project costs about fifty bucks.

Of course, once you draw on the board with the laser, the rest of the process is like it always has been. Develop the board, etch, and all that. We wish the laser could drill the holes as that's the part we hate the worst!

We've seen powerful lasers just cut boards, of course. You can also forego the photoresist and just let the laser burn off a coating of paint.

#laserhacks #laser #pcb #photoresist #printedcircuitboard