The glider instruments need to be tested in a more holistic way...as holistic as you can get when the fuselage is sitting in the garage.

First photo shows tubing attached to the pitot probe. The long external tube allows me to add pressure to the pitot system while looking at the instruments on the panel.

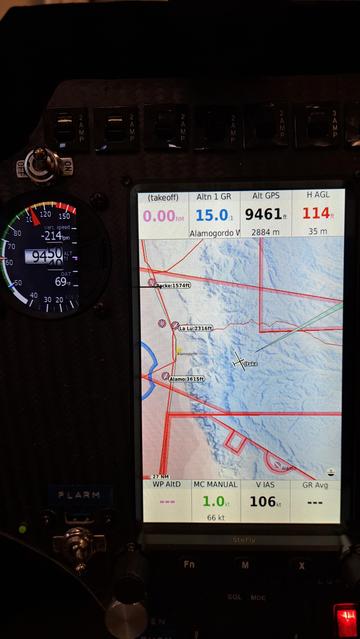

Second photo shows the airspeed indicator (small round display) and glide computer screens. Both of those systems have pitot pressure sensors. I have pressurized the external tubing so that the airspeed indicator shows about 105 knots indicated airspeed. As you can see in the lower part of the glide computer display (V IAS)...the two devices agree within about 1 knot. I can't ask for better than that. (The vario also has a pitot pressure input, but it also uses GPS. It's very confused and angry that GPS says the glider is stationary, but it's supposedly moving through the air at a ridiculous speed. I may have to wait until flight testing to really evaluate the total-system performance of this advanced vario.)

Another bit of good news is that the leakage rate of the pressurized and sealed pitot system is pretty low. After a minute or two the indicated airspeed only drops a few percent at the most. That's not perfect, but it's pretty good.

Third photo shows what the instrument panel looks like when all the devices/screens are running. That's right, if I lose electrical power, my instrument panel is a blank, black hole.

Since I powered up all the screens, it means I'm ready to hook up an ammeter to measure current draw of each device, and my maximum load when everything is running. I'll do that tomorrow.

#AvGeek #Aviation #ElectricAircraft #Homebuilt #Glider #DIY #EAA #Technology #Instruments #Avionics #Test #Testing #Pressure #Airspeed