DIY doings: components, cables and code

I’ve been playing with gadgets ever since my dad let me and my brother take apart an old calculator for fun, but until last week I had never wielded a soldering iron to connect electronic components.

My chance to remedy that oversight came at the end of a tour of a redone Radio Shack store across the street from the Verizon Center Phone Booth in downtown D.C.

After getting the company pitch about its screen-repair services, inspecting some Kodak camera modules made to clip onto phones, and playing with a littleBits synthesizer kit, I was invited to assemble a tiny LED flashlight by soldering the required parts to a small circuit board.

Dripping the molten flux onto the right contacts revealed itself to be a painstakingly precise, hold-your-breath task. I needed coaching from the rep manning that station, after which he had to redo some of my work–making me think this whole project was perhaps more like when our toddler puts together some arts-and-crafts project “with help.” But a few minutes later, I did have my own tiny, battery-powered flashlight.

I had also completed my first hardware tinkering in a while.

The last time I’d cracked a computer’s case was two years ago, when I doubled the memory in my iMac (Apple has since made that at-home upgrade impossible on newer models) and then swapped out my ThinkPad’s hard drive for a solid state drive. Either chore involved less work and anxiety than the multiple transplants I performed on my old Power Computing Mac clone in the ’90s, including two processor upgrades and a cooling fan replacement.

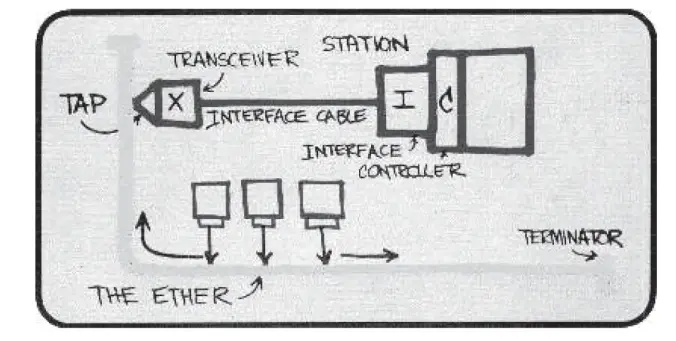

While we’re keeping score, I last seriously messed with wiring when I strung some Ethernet cable from the basement to an outlet behind our TV to prepare for our Fios install in 2010. Going to that trouble, including terminating the bulk cable and attaching plugs myself, allowed me to use my choice of routers on our Internet-only setup.

The crimping tool I used for that task hasn’t seen much use since, but I’d like to think I’m still capable of moving a phone, power, or coax cable outlet. Especially if given a spare length of cable on which to practice first.

My DIY credentials are weakest when it comes to code. I learned entry-level BASIC in grade school but now recall little of the syntax beyond IF/THEN and GOTO. I used to lean on AppleScript to ease my Mac workflow, but now Automator lets me create shortcuts without having to remember the precise phrasing required after AppleScript statements like “tell application ‘Finder’.” My HTML skills now stretch little further than writing out the “<a href=” hypertext link.

I do, however, still grasp such important basics as the importance of valid input and proper syntax, how easy errors can crop up and how much time it can take to step through functions to figure out what threw the error. For anything more complicated, the usual reporting technique comes into play: Ask as many dumb questions as needed to get a little smarter on the subject.

#AppleScript #BASIC #coding #crimpingTool #DIY #EthernetCable #hardwareUpgrade #solderingIron #SSDUpgrade

🐦🔥nemo™🐦⬛ 🇺🇦🍉

🐦🔥nemo™🐦⬛ 🇺🇦🍉