#3dprinting update;

I'm super happy with my build. Unfortunately the upgrade path looks like it's going to force me into #Klipper which has never actually been good to me.

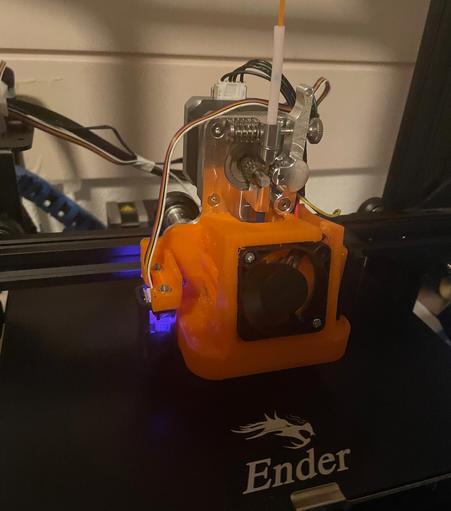

My build currently:

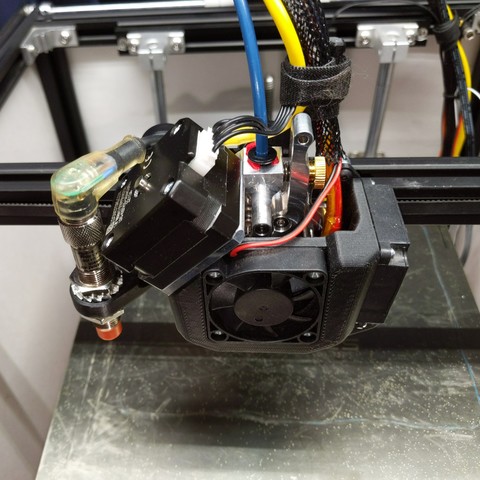

- Ender5 chassis

- #BTT #Octopus mainboard

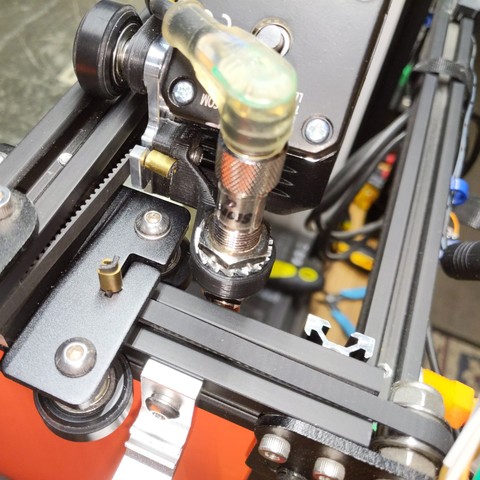

- Modded #Endorphin-- Meaning: Linear Rail conversion-- Partial CoreXY kinematics

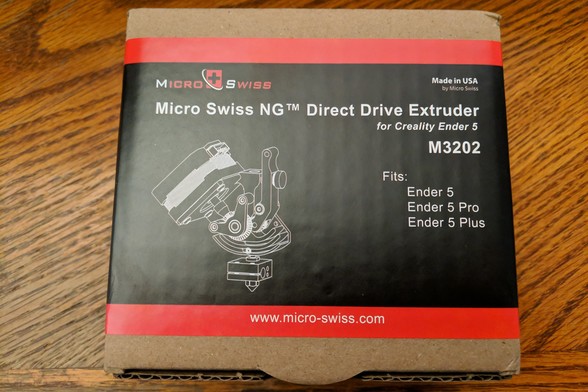

- #microswiss direct drive

- Volcano hot end + 60w heater

- 0.6mm #Diamondback volcano nozzle

- MSDD modded heat break / mount

- Hydra-based cooling solution

- Dual independent Z-screws

- BLTouch

- Mains powered bed heater

- Octopi

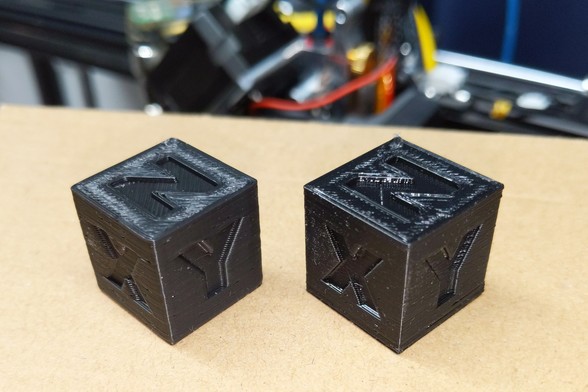

Like many before and similar to myself the Ender platform served as a wonderful platform to build and tinker on. As far as I can find, particularly with my custom work for the Volcano, this is a unique build. I looked at the traditional volcano options but I did not like the #klemco mount options nor the traditional volcano heat break. I was concerned about heat creep but I've seen no signs of it even when printing PC.

At this point I'm looking into the #Eddy bed level sensor, but it's klipper only. Otherwise there's almost nothing I can want from my printer that it cannot do. Multi-material would be nice but there's no good way to do it and MMS' are so damn wasteful. More print volume would be handy but that means changing a lot and I've got spare 235x bed plates for days. The Eddy makes bed leveling super fast and accurate, leagues beyond what a probe based sensor can do. But it also means being unable to come back to Marlin and lose a bit of print volume to the Eddy sensor. So I guess I'll see, if something comes along to convince me to suffer through Klipper's headaches.