So, burned through most of the filament we got for Child.1's birthday. Until we have a chance to order some more, I remembered I had a 2 kg spool from the last time I tried to get into 3D printing and failed.

It's been sitting in my basement for... ten years or so.

But Child.1 also got a filament drier and wanted to try it out.

But the 2 kg spool didn't fit, so we wound some of it onto the 250 g spool... by hand. Then we put it into the drier and turned it on. Child.1 was happy how hot it got and was annoying it was going to take ten hours to finish.

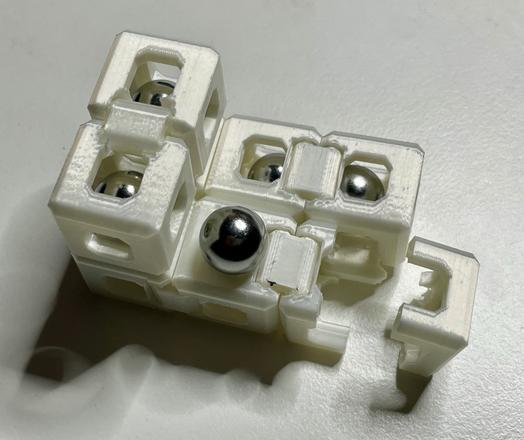

About an hour into it, there was a loud crack as the spool of filament didn't quite explode but the entire spool did break itself into 3-10 cm long segments and turn itself into a porcupine. As we picked it up, chunks started slipping off into a carpet of white strips of plastic.

... I'm going to buy a proper spool of filament that isn't old enough to go to grade school.