One year on: Council leader hails resilience after Port Talbot blast furnace closure

Cllr Steve Hunt said the end of primary steelmaking in the town had been a “seismic change” for the area, but stressed that support schemes and local determination had helped many adapt to life after the furnaces fell silent.

A year since the furnaces went cold

On 30 September 2024, Port Talbot’s last blast furnace was shut down, ending more than a century of traditional steelmaking in the town. At its peak, the site employed around 20,000 people, but by the time of closure the workforce had fallen to around 4,000. Tata Steel said the furnaces were losing around £1 million a day, citing high energy costs, ageing assets and competition from cheaper imports.

The decision brought 2,800 direct job losses, with unions warning that thousands more in the supply chain could be at risk. For a community built around heavy industry, the closure was described as “life‑changing” and sparked fears of long‑term decline.

Yet, one year on, the council leader says the picture is more complex. “Many affected workers have used the Employment & Skills Fund to move forward with their careers, some into entirely new fields of work or even emerging industries such as AI,” said Cllr Hunt. “Others have started their own businesses or diversified existing ones. It has been inspiring to see how our communities have responded to the challenges this has brought.”

The final ‘push’ at Morfa Coke Ovens in Port Talbot, captured at 10:47am on Wednesday 20 March 2024, marking the end of almost 50 years of coke making at the site. (Video: Tata Steel)

Support and adaptation

To soften the blow, the UK Government pledged £80 million in transition funding, delivered locally through a series of support schemes. These included retraining programmes, grants for supply‑chain businesses, start‑up support for new ventures, and resilience funding for firms looking to diversify. Mental health services were also expanded, with organisations such as NPT Mind offering counselling and wellbeing programmes in schools.

According to figures presented to the Tata Steel / Port Talbot Transition Board, the funds have already helped dozens of businesses and thousands of individuals. More than 3,600 training courses have been completed, over 300 people have found new jobs, and nearly 600 Tata employees have been redeployed within the company. Despite the scale of the redundancies, council leaders say there has not been a significant spike in unemployment locally.

Neath Port Talbot Council leader Cllr Steve Hunt pictured in hi‑vis during a visit to Port Talbot Steelworks, reflecting on the site’s transition to greener steelmaking.

(Image: Neath Port Talbot Council)Looking to the future

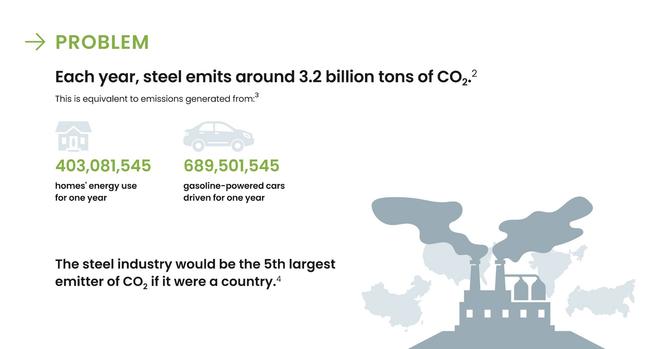

While the closure of the blast furnaces marked the end of an era, Tata Steel has committed to building a new electric arc furnace at Port Talbot by 2027–28, backed by £500 million of UK Government funding. The move is expected to slash carbon emissions and secure a future for steelmaking in the town, albeit with a smaller workforce.

Alongside this, the SWITCH research facility at Port Talbot Harbourside and the Celtic Freeport project are being hailed as signs of a new industrial chapter. “These developments will see a new place for steelmaking which, alongside major projects such as the Celtic Freeport, give us cause for optimism as we adapt to what has been a seismic change for the whole area,” said Cllr Hunt.

A community in transition

For many in Port Talbot, the past year has been one of uncertainty and adjustment. Community groups have reported a dip in morale, but also a determination to find new opportunities. The council leader insists that the support on offer is making a difference and urged anyone affected to seek help.

“Change on this scale is never easy,” he said. “But the resilience of our people and the willingness of businesses to adapt shows that Port Talbot has a future beyond the blast furnaces.”

Further details of the support schemes are available at www.npt.gov.uk/tatatransition.

Related articles

#CelticFreeport #CllrSteveHunt #employmentAndSkillsFund #featured #greenSteel #industry #jobs #NeathPortTalbotCouncil #PortTalbot #PortTalbotHarbourside #PortTalbotSteelworks #steel #steelworks #SWITCH #TataSteel #TataSteelworks