I’ve today off so naturally I’m trial firing the remaining track on the second reverse loop before I take out the corner board for one last time to fit the backscenes to the back and side of that board.

Busy day today. (1) Gluing down the inner helix

Back in May and June 2020, lockdown restrictions gave me time to work on the extension, which at that point had only reached as far as the second bridge. The next step (for both phases 2 and 3) of the extension involved making holes including one for gaining access to the shed for stock storage.

The making of the holes (as recorded in a virtual meet-up post at the time) took place on 9 May:

Having made the holes, I began to lay the trackbed (a mix of decking a larch planks), whilst also working on a semi-covered area alongside the shed, through which the mainline passed. While this would be a general storage area, the roof created what would become for the next year a temporary covered steam-up area (which is still occasionally used, although it’s not ideal, sited on the ‘main line’). The roof is not yet fixed here on 23 May:

By 2 June I was laying track, and by 3 June this reached into the shed.

Fortunately the weather remained fine, because it wasn’t until 20 June that I actually got the shed door (for trains) fixed in place!

In July I shot a driver’s eye video of the line starting an ending from inside the shed, for a virtual meet-up. This is the second attempt (the previous one, a couple of days earlier, having been pretty much unwatchable!)

https://www.youtube.com/watch?v=tUI1DvnuGZ4&t=1s

Inside the shed, the plan was to create a shelf-based cassette system for train storage. But I found that the capacity for simply having one train coupled up and ready to go was so transformative, the motivation to actually build the shelves diminished, and it took me another year to get round to this…

The most delayed post on this blog (so far) I meant to write this 8 years ago, it was a planned 2-parter with Building Bridges (1) describing two alternate styles of removable bridge. The second bridge itself was complete before I’d written up the first!

Since then the plan for this post has gone through 3 iterations: originally intended to be a quick summary of the key design points, within a year or so it had become clear that I shouldn’t have built either bridge out of wood, as expansion and contraction in the wet and dry weather meant the bridges didn’t just drop or swing into place. This post was going to be a ‘how not to do it’.

Then lockdown came and I just wanted to run trains. And I realised that spending a minute or two each running session was actually much quicker than building new (possibly aluminium) bridges, especially in a situation where materials were not readily available! The bridges got a reprise, and still function today.

Building Bridges 1 described a very simple lifting bridge, bridge number 2 at around waist height is longer – it could have been a lifting bridge too but it would have lifted high, and swinging it seemed like it would be easier to do. So the design is modelled on a gate – I even originally used a gate latch.

In July 2016 I sunk the posts in exactly the same way as for the first bridge.

The gate bridge, openThe gate bridge, closedI thought of it as a gate. I put a post down the hinged side of the ‘gate’ and braced the ‘top’ of the gate, which of course was the trackbed, with a crosspiece. The rest of the gate I missed out…

I put a gate latch on to keep it closed, but also to hold it open.

The ‘close’ latchThe ‘open’ latchThis turned out to be a poor design choice, providing no precision in vertically or horizontally aligning the track.

I angled the trackbed end, so that the corners of the trackbed ends on the bridge and the abutment would not foul each other.

The approach to the bridge, showing the angleSide view of the angled joinTop view of the angled joinThis was a better design choice, enabling me (with a bit of force) to swing the gate into position in all conditions. The gate latch has long gone, replaced with a washer underneath to align horizontally, and a bolt to hold the gate shut.

My ultimate plan is still to replace the bridge, probably with something in aluminium, at least for the longitudinal supports. Shortly after building these bridge I was involved in assisting with constructing the raised level garden railway at Cardiff MES and we created bridges with aluminium bearers parallel to the track and wooden cross pieces. They are light and fit perfectly into place every time.

Cardiff MES Bridge, closedCardiff MES Bridge, openBut the urgency to replace my bridges has gone. Trains make it across the joins (just) and other parts of the trackbed are in more urgent need of upgrade (another story). I might even print some cosmetic rails and girders to make the bridges look more scenic, until the big reconstruction…

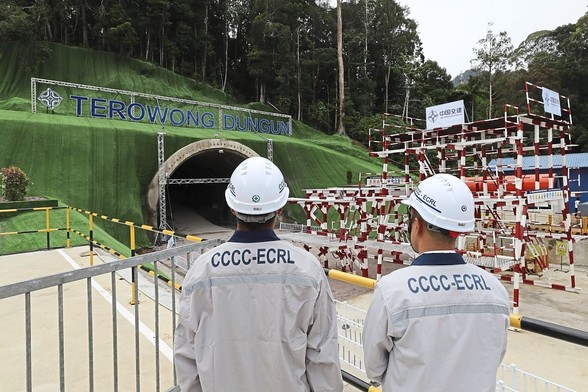

The #track #installation for the first phase of the #EastCoastRailLink (#ECRL) project, spanning from #KuantanPortCity (#KPC) in #Pahang to #Dungun in #Terengganu, covering a distance of 92km, has been accomplished a month ahead of the projected schedule

The achievement was attributed to the innovative CCPG-500A track laying machine, marking a pioneering advancement in the nation's #rail sector

#EastCoast #railway #trackinstallation #raillink #tracklaying

First phase of ECRL track installation ahead of schedule

KUANTAN: The track installation for the first phase of the East Coast Rail Link (ECRL) project, spanning from Kuantan Port City (KPC), Pahang, to Dungun, Terengganu, covering a distance of 92km, has been accomplished a month ahead of the projected schedule.

The first track has been laid for #EastCoastRailLink (#ECRL) in #Gebeng, marking the dawn of a new era in the country's mega-rail project.

Yang di-Pertuan Agong graced the official #inauguration of the #tracklaying ceremony at the Section 10 ECRL #station site.

This marks the beginning of a crucial 94km #track laying works from #Kuantan Port City (#KPC) station in Gebeng to #Dungun, #Terengganu, and is expected to be completed in three to four months.