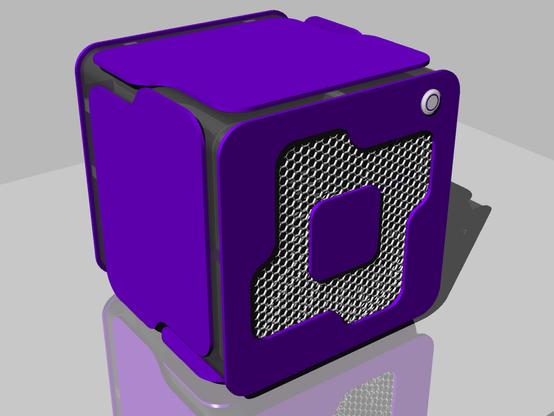

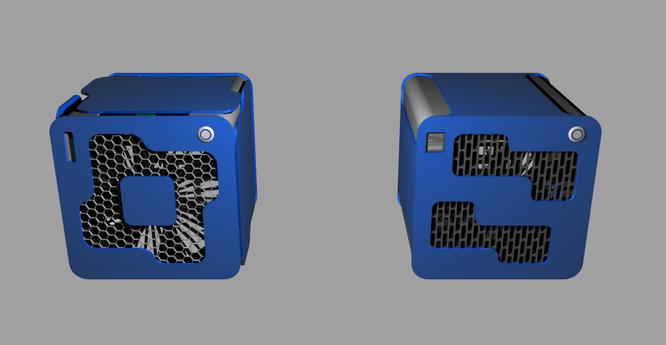

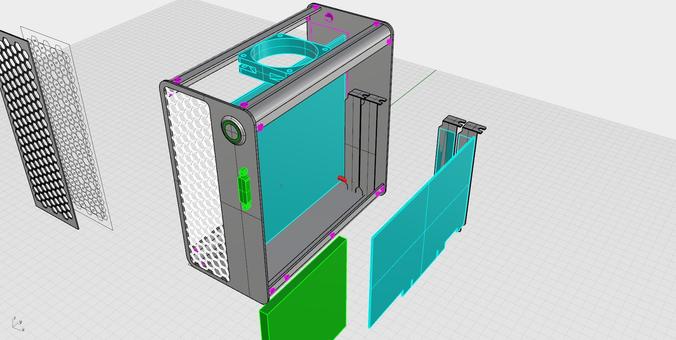

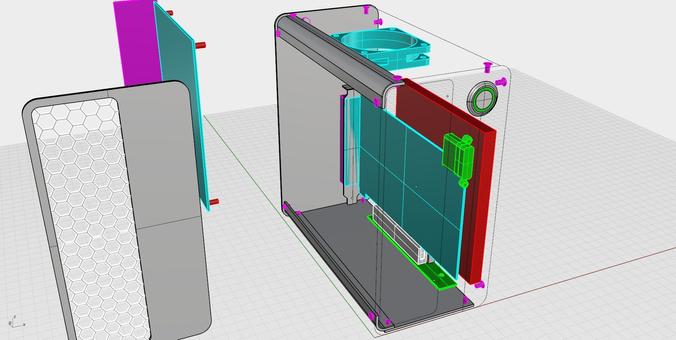

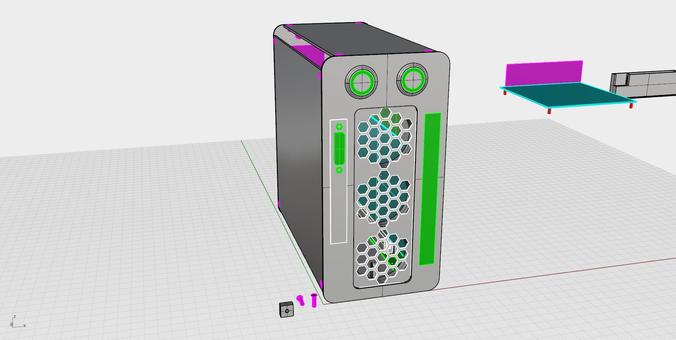

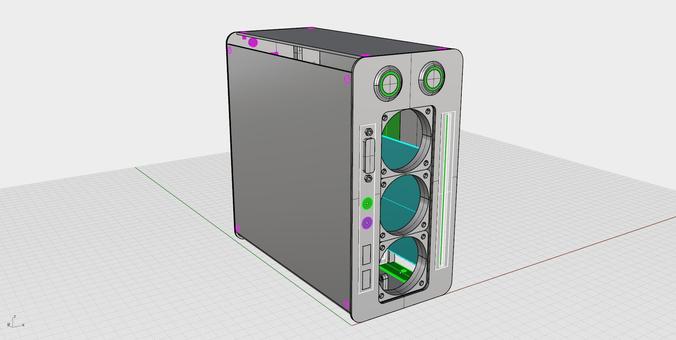

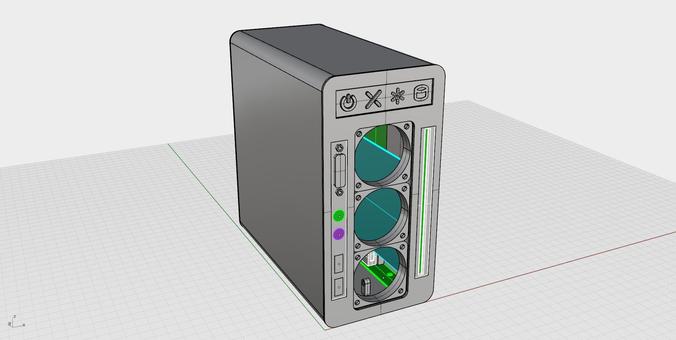

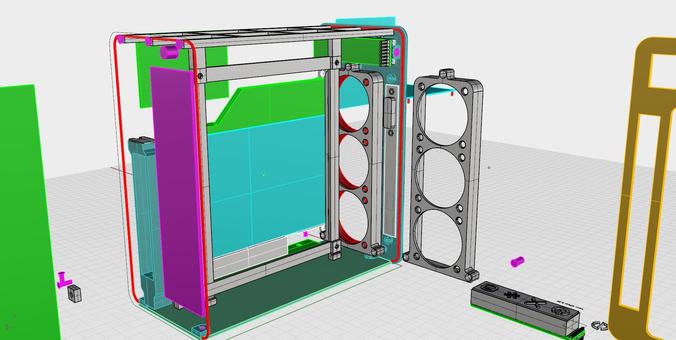

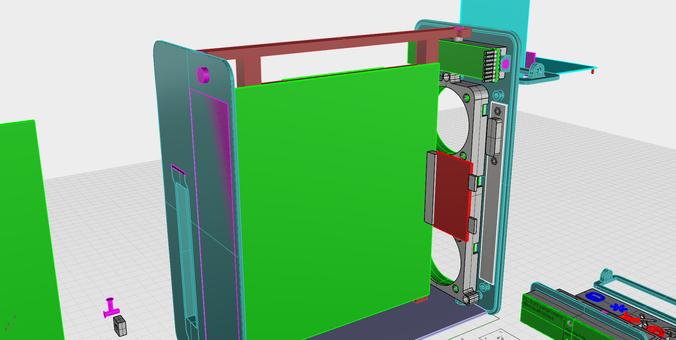

I'm sick with another cold or something, so I'm idly sketching out a 3D printable case for an ITX retro gaming rig, the primary feature of which will be a 15-pin gameport socket up front.

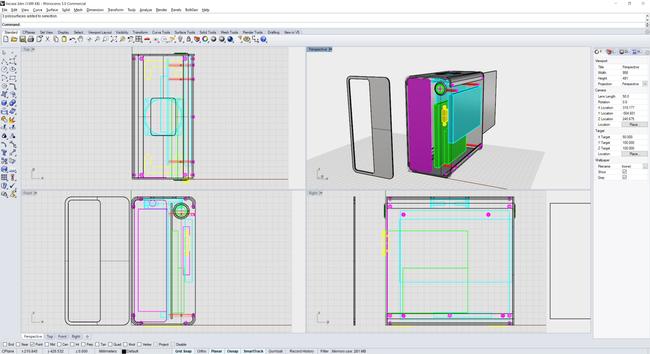

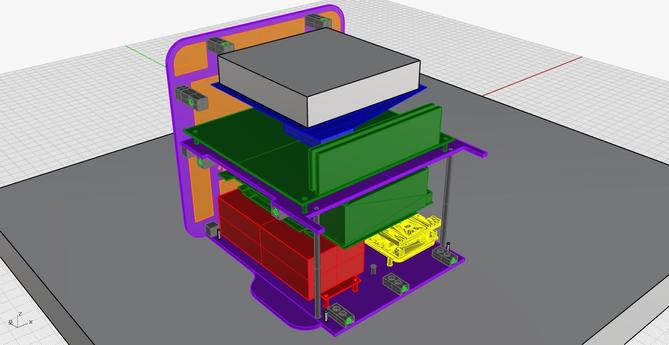

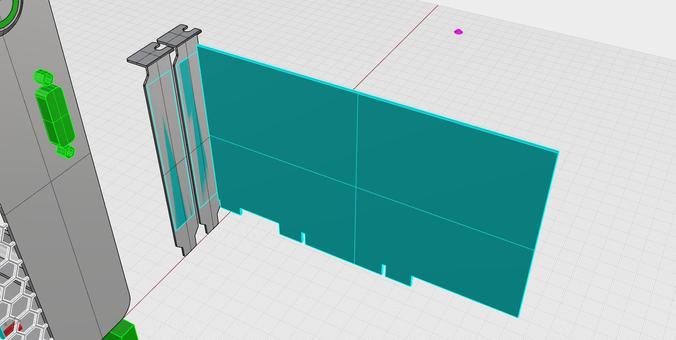

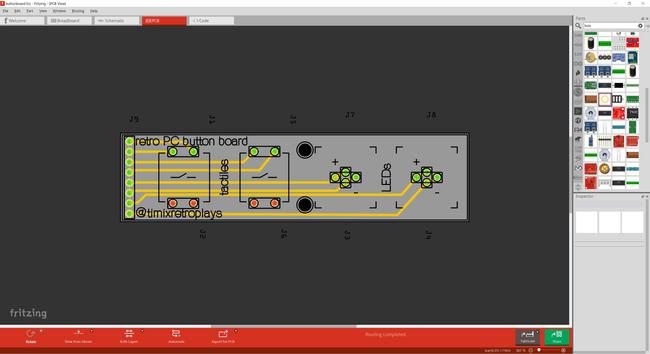

I've started a few projects like this, but never run them right through to the end - if you've ever wondered what designing a PC case is like, just draw a whole bunch of differently shaped rectangles and try putting them neatly in a box. Dunno yet if this one will see the light of day beyond this screenshot.