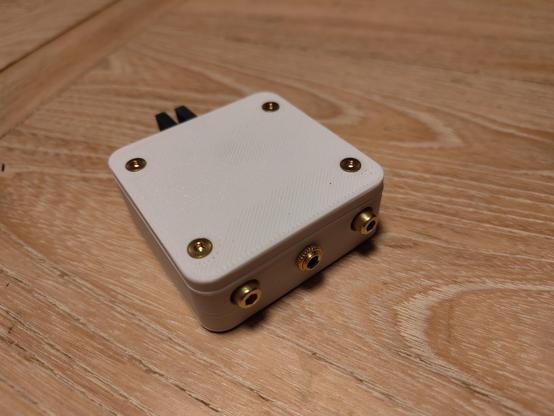

I'm chuffed to bits with my second try at making a 3d-printed CW paddle. One that is adjustable in all the right ways, that is smooth and that I can throw in a bag.

Files available here: https://www.thingiverse.com/thing:7045539

A Better Iambic Morse Paddle by dramaturg

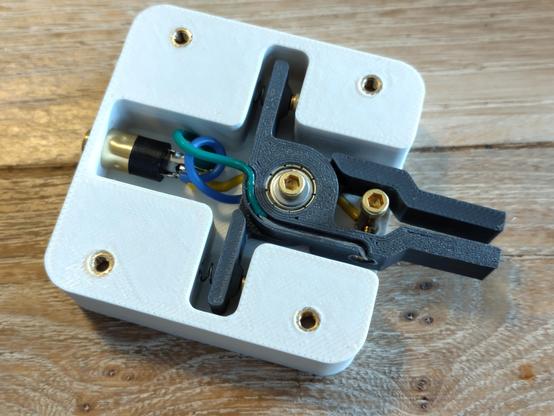

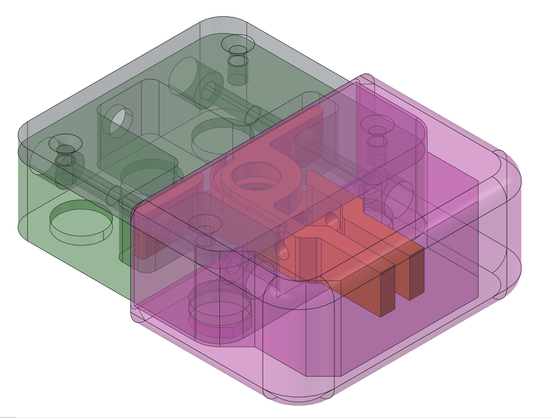

This is better. Not better as in "better than everybody else's" but rather better than my first attempt at making a paddle before I even started learning CW. I quickly realized that one really wants to be able to fine-tune contact distance as well as the force required and this is what I came up with.The result is a bit of a mash-up of different ideas I've seen around the interwebs as well as in my local club.There is also an optional cap so the paddle can be thrown into a bag without worry.Hardware required:8x M3x4 heat set inserts. M3x3 would work just as well. Four to keep the lid on, two for the center contact and paddle pivot and two as contacts in the paddles.4x M4x20 cap head screws for adjustment (or similar)4x M3x6 countersunk screws for the lid.2x M3x16 screws for the center contact and paddle pivottwo pieces of 4mm brass pipe (3mm I.D.). I guess you could get away with using M4 instead but this worked nicely for me. The center pivot piece is about 9mm, the center contact piece is 12mm long2x bearings 604-2Z or 604-Z 4x12x4mm. Fix them to the paddle with super glue to ensure nothing wobbles.2x Springs 4x10mm (3mm would work too)2x M3 grub screw (M3x8 would work as well, I think) for Paddle contacts6x Magnets 12x2mm (8x if you also print the cap)1-2 M3 washers. One at the top of the bearing, another to fine-tune the paddle spacing if necessary1x 3.5mm audio socketWires. See picture on how I routed those but it should be pretty straightforward. Use a bit smaller gauge than I did to make it even easier on you. Fix them in place with super glue.