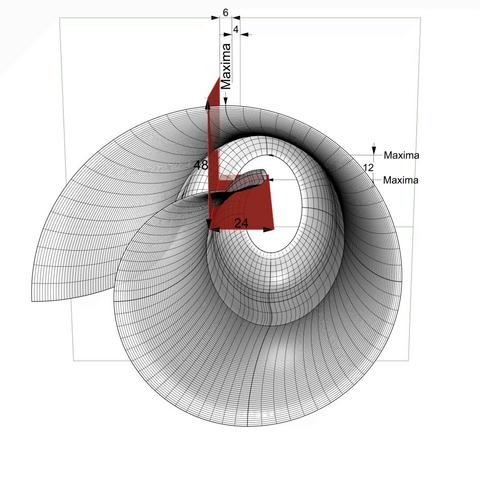

First draw an L shape that is 3 parts (24 units) wide and 6 parts (48 units) tall. The base of the L should align with the maxima of the last arc of the rear #spiral. The stem of the L should be 3/4 part (6 units) to the left of the maxima for the first arc of the front spiral, or 10 units to the left of the eye of the spiral.

#Extrude the L-shaped curve to create an L-shaped #cuttingSurface (shown here in red) that extends past both the front and the rear of the scroll surface.

Make a copy of the scroll surface so that you don't destroy the full original surface. Then, split the copy of the scroll surface with the cutting surface.

From the outside portion of the scroll surface, discard the portion to the left of the cutting surface, From the inside portion of the scroll surface, discard the portion immediately above the base of the cutting surface.

Save a copy of the cutting surface in case you need to repeat these steps, because in the next step we will carve out a portion of the cutting surface itself and join the flat faces of that carved out shape with the trimmed scroll surface.

Splines (@Splines@pixelfed.social)

Compare the image here with that in https://pixelfed.social/p/Splines/794551798960473148 for smoothness. When we discard the bands immediately adjacent to the front and rear bands (one between K and P and the other between Q and L in https://pixelfed.social/p/Splines/794105734853818690), we are left with three bands. The front band is 36 units deep the middle band between the frames marked P and Q is 25 units deep, and the rear band is 18 units deep. We then split the middle band into two — a band 18 units deep adjacent to P and a band 7 units deep adjacent to Q. Finally, we perform a #surfaceBlend between the front band and the narrower split band while maintaining tangency. This produces a new band that is 32 units deep. We perform another surface blend between the rear band and the wider split band maintaining tangency. This produces a new band that is 14 units deep. We then discard the two bands that we had split from the original middle band. The end result is 4 bands total — A front band that is 36 units deep, a blended band 32 units deep adjacent to the front band, a blended band 14 units deep adjacent to the rear band, and the rear band that is 18 units deep. When we join these 4 bands, we get the full #scroll surface that is 100 units deep. The final surface is smooth, and there is no hint of banding, as seen in this image with a polished gold #environmentMap. This is the smooth surface whose back view is shown with a #zebraPattern in my introductory post at https://pixelfed.social/p/Splines/789956327130679640 and again in https://pixelfed.social/p/Splines/792828550887335575. We were finally able to coax the scroll surface not just to "hug" the #modulatingSpirals, but also to stretch tightly and smoothly. We have come a long way, but there's still more work to do. What we have right now is an open surface. We need to convert this into an #airtight closed object that we can use for #3DPrinting or #CNCMilling. We will do that in the next posts.