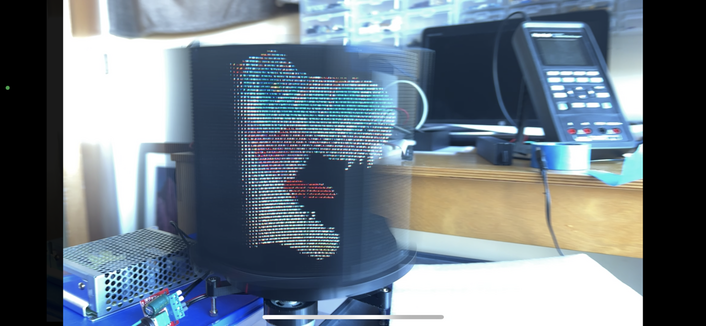

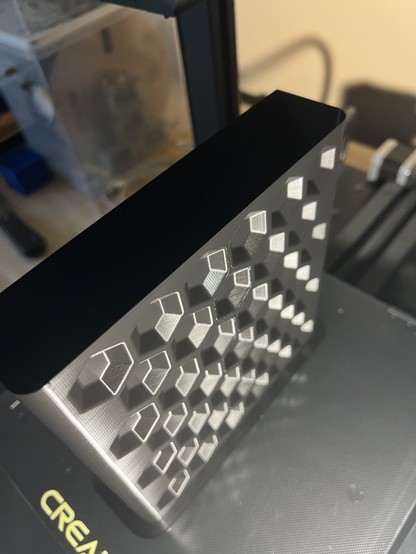

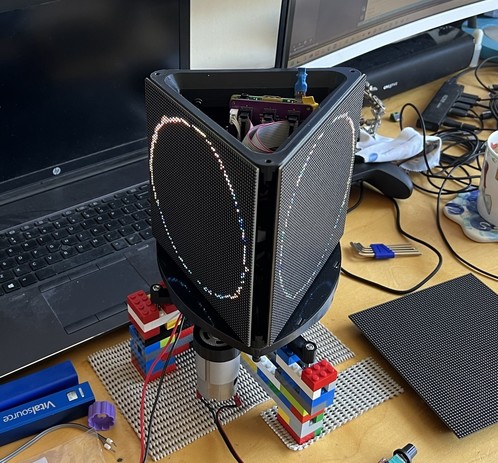

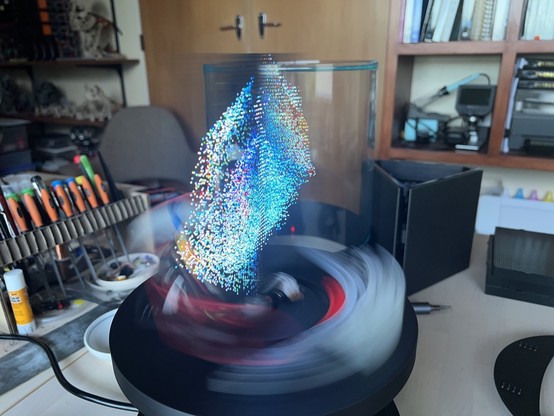

I went back to the slats, and finally got all the bits hooked up together.

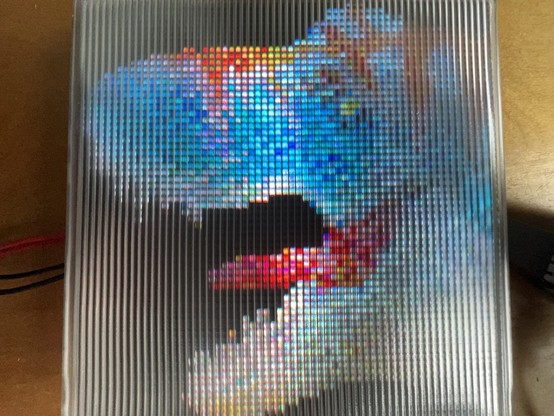

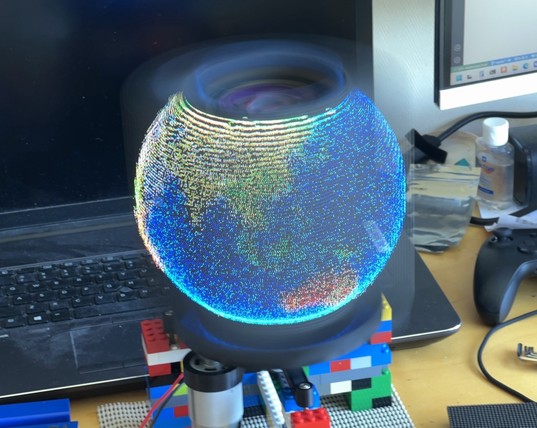

It sort of works?

The thing I've been trying to make creates its 3D effect by displaying a whole different view in every direction, which means it can handle occlusion and fancy lighting at the cost of vertical parallax.

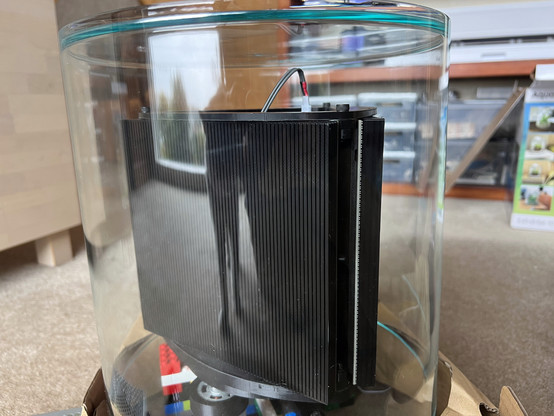

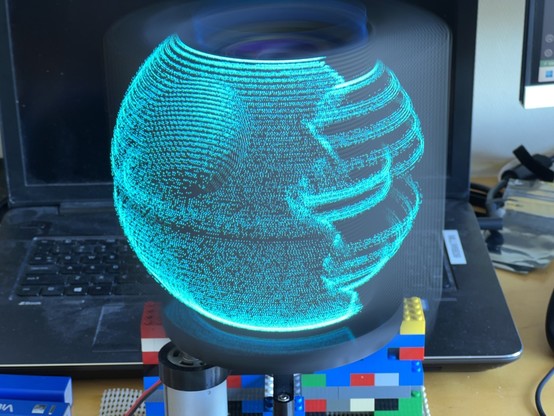

To turn that setup into a swept volume (where it's lighting up the LEDs according to where they are in space - full 3D, but glowy and transparent) I keep everything but the collimators, and just render each view with the near & far clip planes set really close together.

However, if you want to sweep one around an axis, you ideally want to update the outer LEDs at a faster rate than the inner ones, and this layout prevents that.

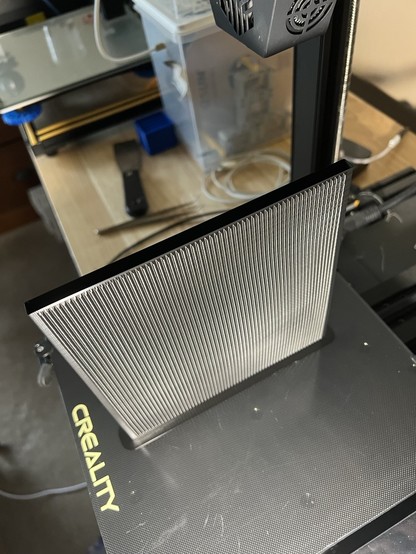

Scouring Aliexpress for LED panels for the new display, and it seems the higher resolution ones tend to be flexible. I spent a while investigating developable surfaces* to see how I could take advantage of this, but couldn't come up with a layout that offers any advantages over a flat square centred on the axis. Seems disappointingly pedestrian.

(*Twisting a sheet of paper in my hands)

If you squizz your eyes at this, you can see the 3D.

If you have difficulty converging it, it helps to make the image really small and gradually enlarge it once your eyes have locked on.

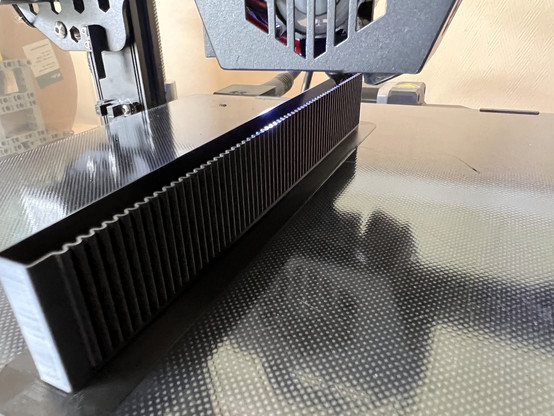

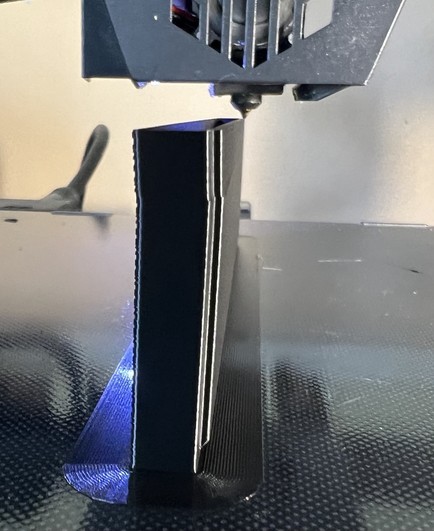

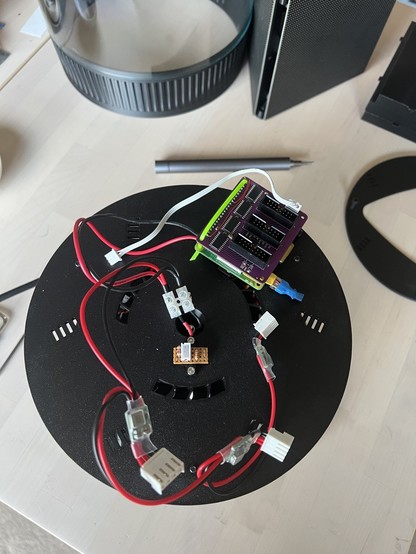

I've reworked it to use a belt drive instead of the horrible 3D printed gear - before, it screamed; now it whirrs.

@ancientjames it already is absolutely stunning!!

Makes me wonder, what's used for the display driving right now?

Maybe you mentioned already, maybe not. But it'd be neat to slap in a FPGA there to really push the data rate and maybe get some colour depth back!

I made some good experiences, speed-wise, with a mix of Binary modulation and PWM to get low data rate and good brightness.

@ancientjames

I met a fellow at #EMFcamp that built replica #R2D2 - he doesn't know that he needs to build one of your masterpieces for the top...

#EMF #Starwars #holograms #models #modelling #voxels #graphics #scifi

And LEGOs! Can't forget the LEGOs!