#fab25 #bridgethegap #prusa #printfarm #fabacademy #fabfoundation

Visit to the Prusa factory in Prague Wednesday.

#fab25 #bridgethegap #prusa #printfarm #fabacademy #fabfoundation

#fab25 #bridgethegap #prusa #printfarm #fabacademy #fabfoundation

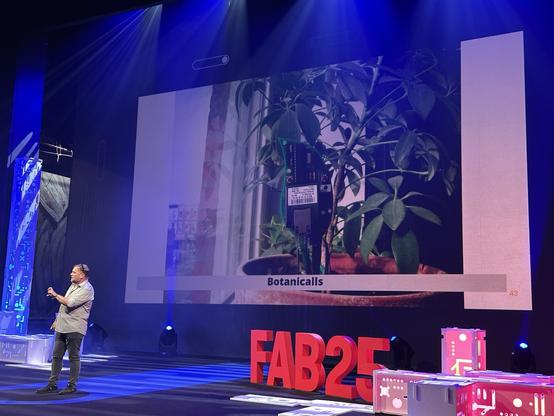

Really nice venue in Prague for the second part of fab25: the spiral at the expo with a rotating stage.

#fab25 #bridgethegap #fablab #fabacademy #fabfoundation #makerspace

#fab25 #bridgethegap #fablab #fabacademy #fabfoundation #makerspace

Check out the story of Camilla Luna. Her final project is amazing and she already turned that into an organisation before her fabacademy graduation this evening.

#fablab #fab24 #bridgethegap #fabacademy

https://www.moonmakers.org/

#fablab #fab24 #bridgethegap #fabacademy

https://www.moonmakers.org/

Amazing story of Simon Klinga (still only 17) leading a team of now 35 high school students having launched a satellite to clean up our orbit from debris.

#fab25 #bridgethegap #fablab #LASARsat #fabacademy #fabfoundation #brno

#fab25 #bridgethegap #fablab #LASARsat #fabacademy #fabfoundation #brno

The story of Dave Hakkens #preciousplastic continues.

#fab25 #bridgethegap #fabacademy #fabfoundation #fablab

#fab25 #bridgethegap #fabacademy #fabfoundation #fablab

Key note speaker Massimo Banzi, founder of Arduino on the 2nd day of fab25.

#fab25 #bridgethegap #brno #fabacademy #fablabs #arduino

#fab25 #bridgethegap #brno #fabacademy #fablabs #arduino

Currently at the opening of fab25 in Brno.

#fab25 #fabfoundation #fabacademy #fablab #fabricademy

https://fab25.fabevent.org/

#fab25 #fabfoundation #fabacademy #fablab #fabricademy

https://fab25.fabevent.org/

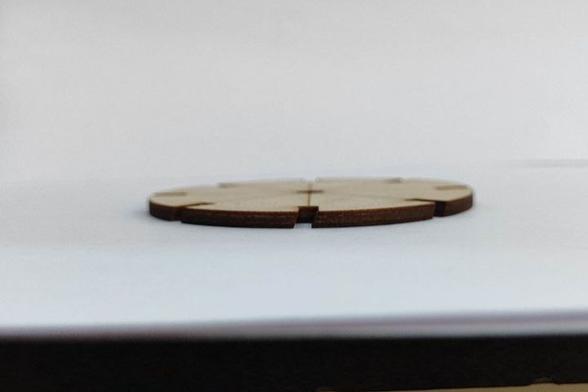

Good documentation by Mkhitar on making angled cuts with a laser cutter.

https://fabacademy.org/2025/labs/dilijan/students/mkhitar-evoyan/assignments/week03/#cutting-part

@vik Not bad! From idea to product in 1 day! That's the main reason i like this network! :-)

https://www.printables.com/model/1339263-fab25-lock-picking-set

Hopefully we have a Fiber laser available at the event!