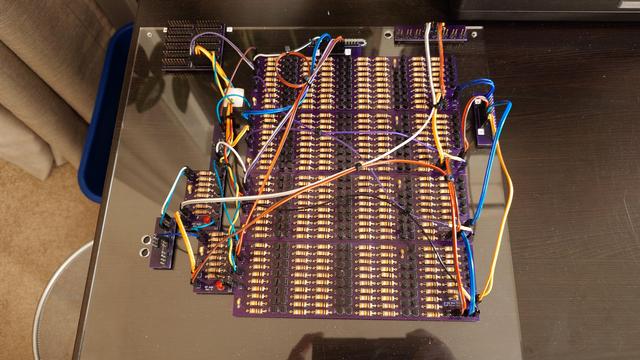

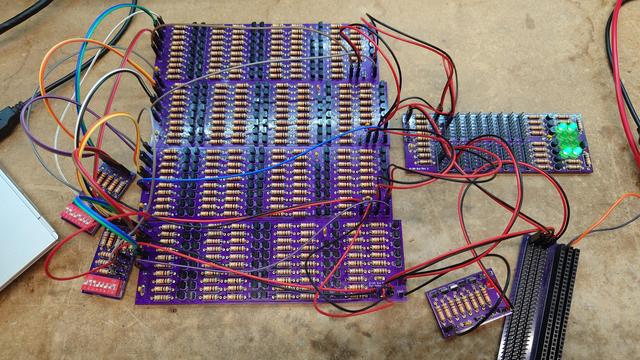

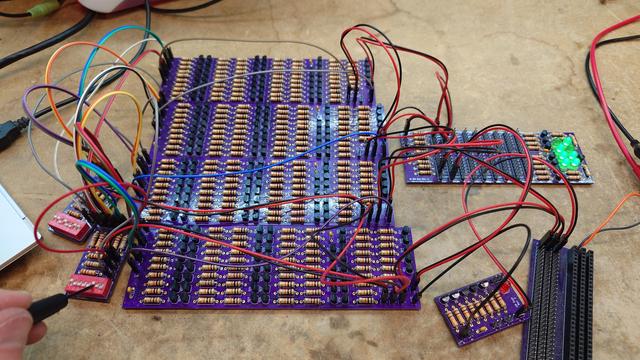

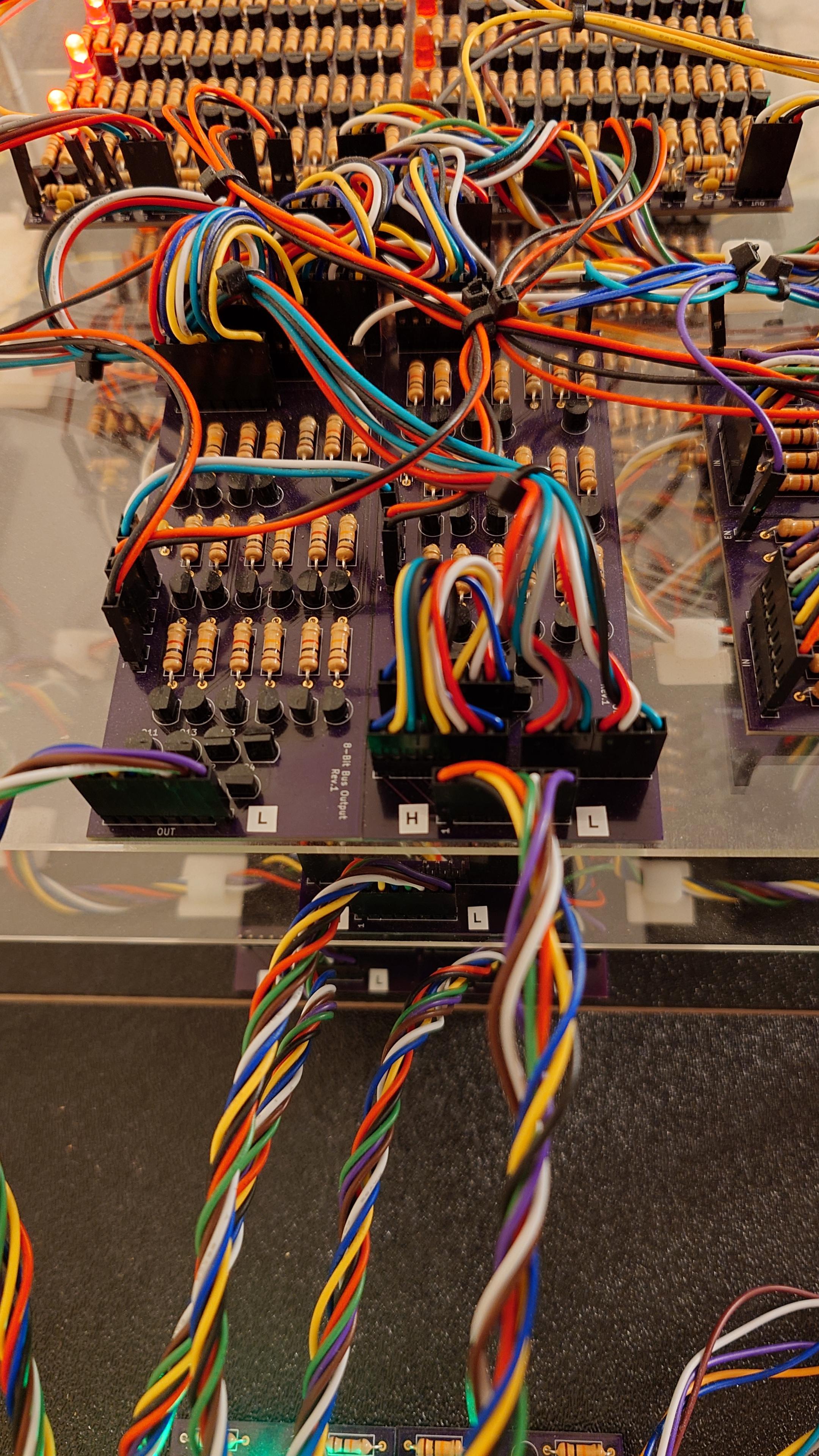

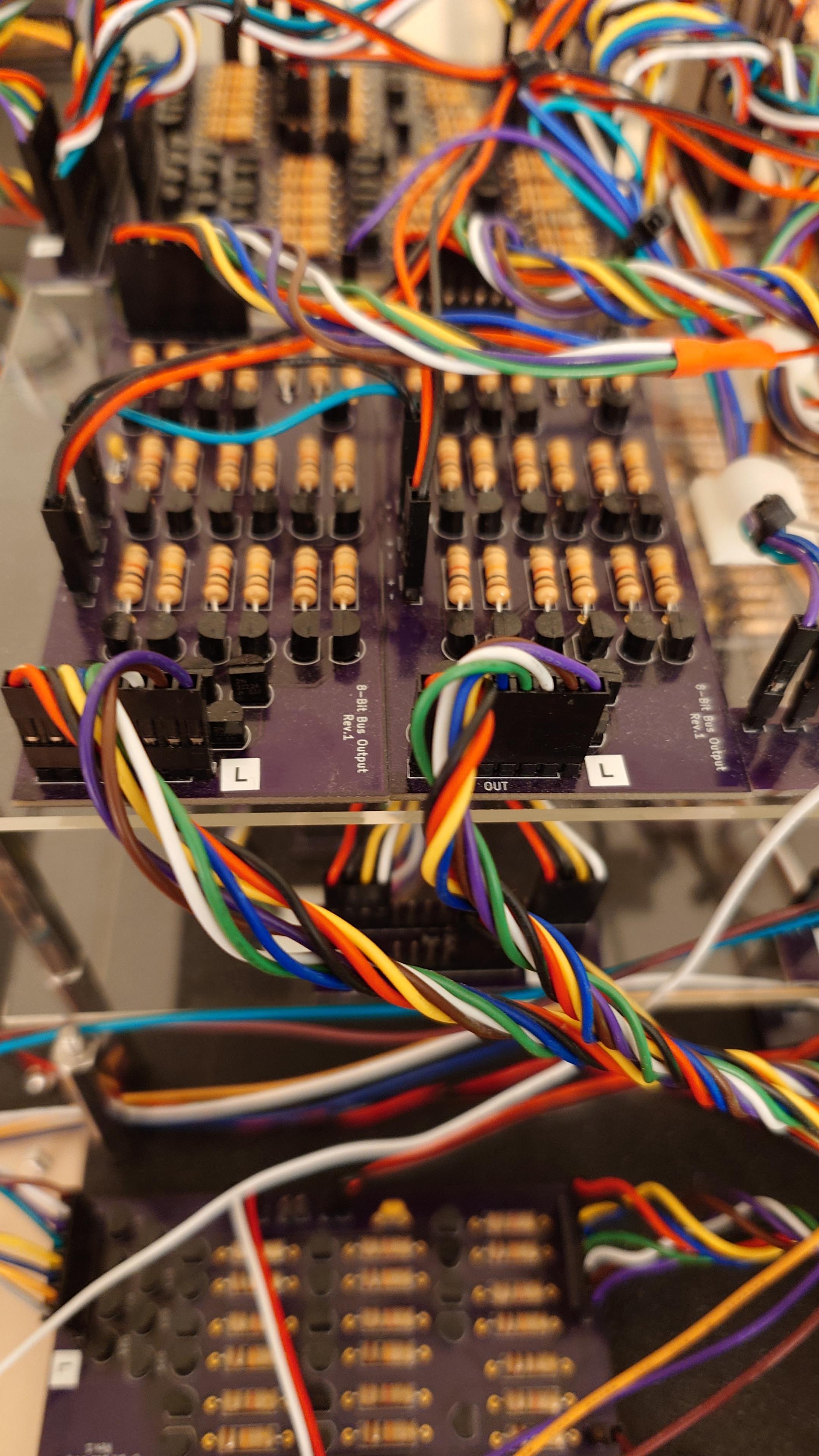

Procrastinated on actually putting together a MiniDragon acrylic board by updating the layout KiCad file to include the upcoming adder circuit. Neat, the documentation is now more up-to-date than the actual CPU.

Anyway, I have the designs and parts brought up to make one more acrylic board of the ALU, and after bringing up the other adders I'll be able to make another acrylic board. That leaves just the shifter circuits to be designed, fabricated, brought up and then placed on board number 5 to complete the ALU. When it rains, it pours.